Dublin San Ramon Services District hired SSB to turn a “triple play” and complete three different roof coating projects at the same time. This approach enabled our experienced 4-man crew to work more efficiently, and the entire 17,350 SF project was completed in less than 90 days.

The first roof was a 4,350 SF tar and gravel roof. SSB crews started by removing and disposing of 19 tons (!) of gravel, then pressure washing the entire surface. After applying an elastomeric basecoat and topcoat, they applied 40” polyester fabric over the entire roof surface and inside parapet walls, followed by a base coat and topcoat of elastomeric coating, then the final two coats to a thickness of 12 mils per coat.

The other two structures had metal roofs of 10,000 SF and 3,000 SF. For these, SSB crews first cut out any deteriorated sections and repaired with sheet metal. They conducted thorough inspections to identify areas of rust and apply RustShield inhibitive primer as needed. They then applied an elastomeric coating with polyester fabric at all panel laps, seams, penetrations, and around skylights, sealed all fastener locations, and applied a final elastomeric coating to a thickness of 12 mils over the entire roof surface.

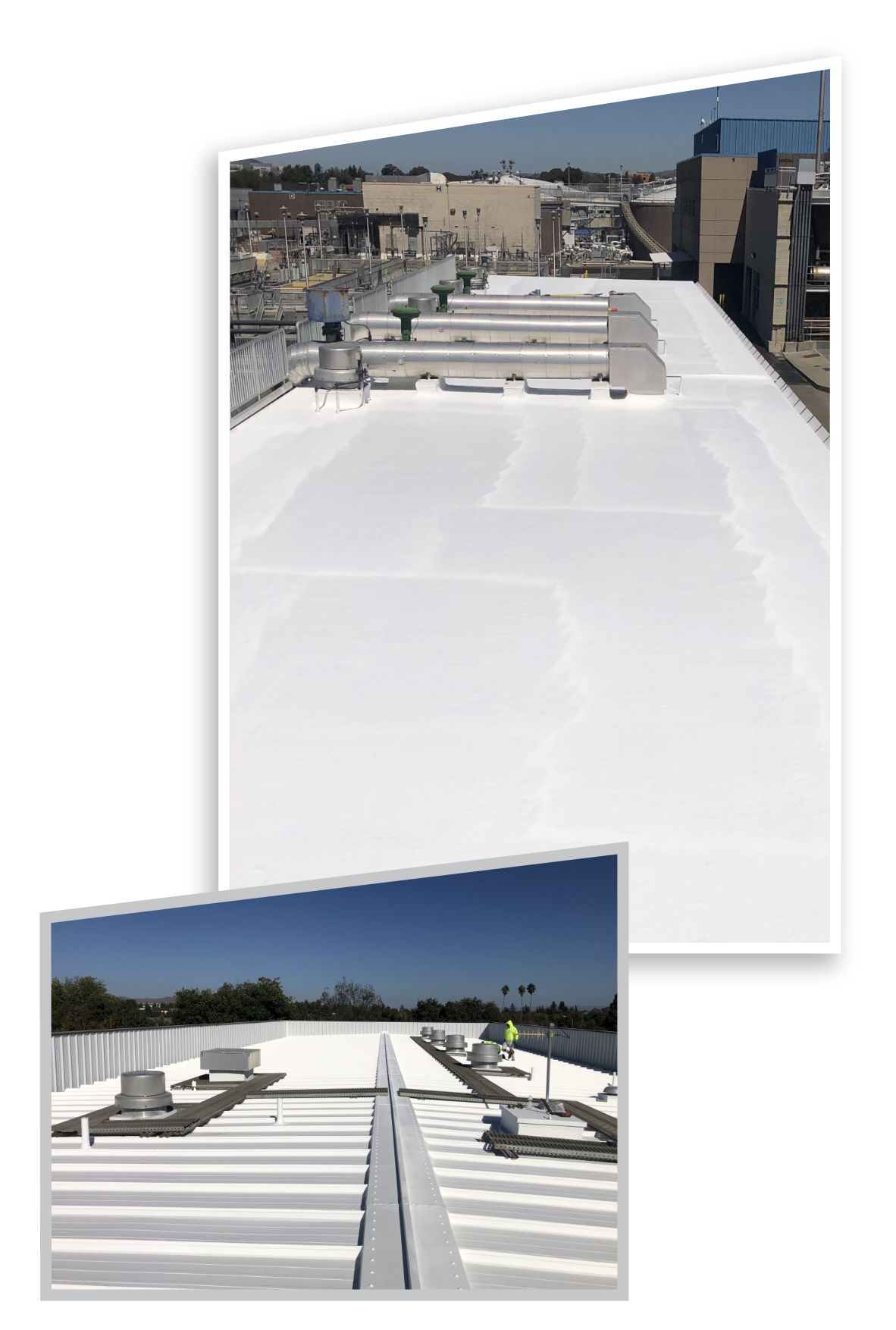

As you can see in the photos below, all three roofs are now fully sealed and coated to provide waterproofing as well as energy savings for many years to come.

METAL ROOFS